This innovation is not just reshaping how cars are designed and produced but also revolutionizing the entire workflow from prototype to production. In this comprehensive exploration, we delve into the myriad ways 3D printing is setting new standards in automotive manufacturing, making what was once thought impossible, possible.

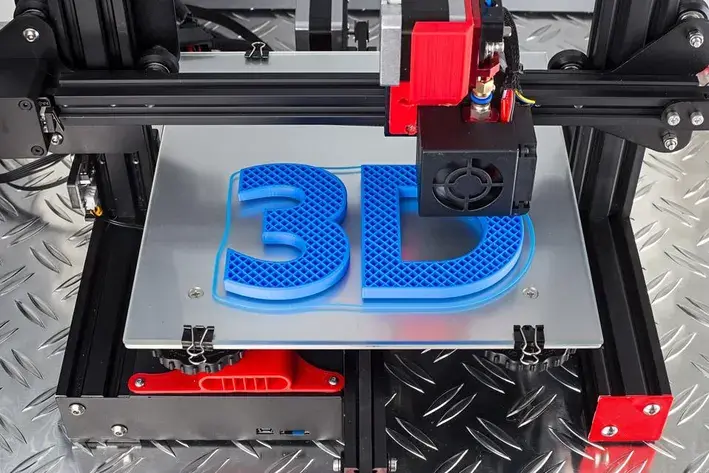

What is 3D Printing and How Does It Work in Car Manufacturing?

3D printing, or additive manufacturing, builds objects layer-by-layer from digital models, contrasting sharply with traditional subtractive processes that remove material to shape an item. In car manufacturing, industrial 3D printers bring a paradigm shift by allowing complex parts to be created with less waste and greater design flexibility. They employ a variety of techniques, each suited for specific applications, ranging from prototyping to the production of final car parts.

What Are the Main Types of 3D Printing Technologies Used in Car Manufacturing?

Several 3D printing technologies have found their way into the automotive industry, each offering unique advantages and challenges.

Fused Deposition Modeling (FDM)

FDM works by extruding thermoplastic filaments through a heated nozzle, layer by layer. It's widely used for prototyping because of its cost efficiency and speed.

Stereolithography (SLA)

SLA uses an ultraviolet laser to harden liquid resin into a solid plastic in a process called curing. It's renowned for high precision and finish quality, ideal for detailed components.

Selective Laser Sintering (SLS)

SLS involves lasers that sinter powdered material, bonding it together to form a solid structure. It’s useful for complex, durable parts without the need for supports.

Direct Metal Laser Sintering (DMLS)

Similar to SLS, DMLS fuses metal powder into a solid part. It’s pivotal for producing high-strength, metal components critical in automotive engineering.

Binder Jetting

This technology binds powder with a liquid binding agent, offering a faster and less expensive means to produce metal parts that are later sintered.

Electron Beam Melting (EBM)

EBM uses an electron beam to melt metal powder, beneficial for its high-quality metal parts and suitability for high-stress components.

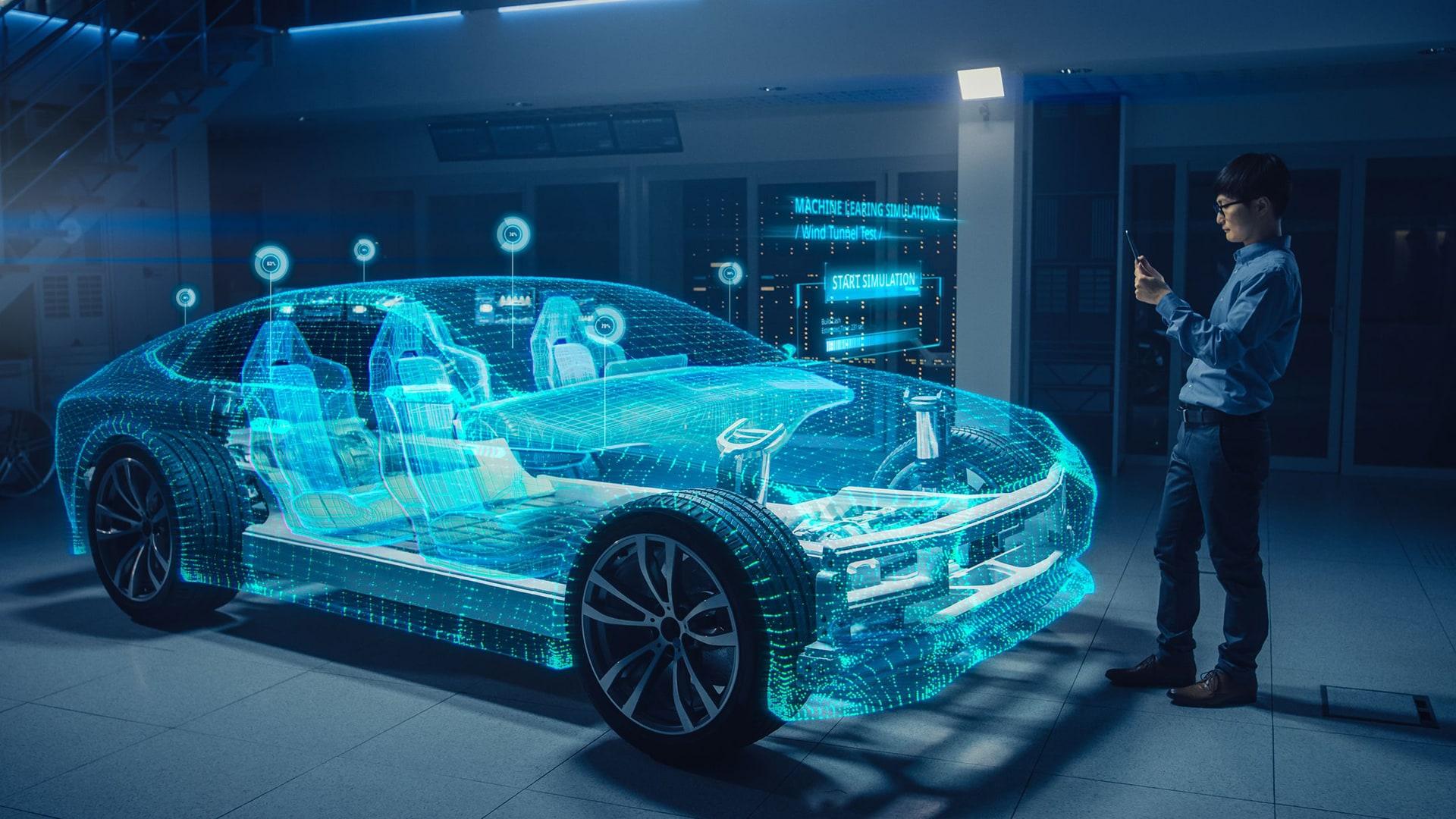

How Has 3D Printing Transformed the Design Process in Car Manufacturing?

3D printing has revolutionized the automotive design process by significantly reducing the development time from concept to prototype. Designers now enjoy unprecedented flexibility to iterate and refine their models quickly. For instance, complex designs that once required multiple parts can now be printed in a single, intricate assembly, reducing both time and material costs.

What Are the Benefits of Using 3D Printing for Prototyping in Car Manufacturing?

●Speed of prototype creation: Rapid prototyping turns ideas into tangible products in days instead of months.

●Cost efficiency: Significant reductions in waste and the need for fewer materials drive down costs.

●Flexibility in design testing: Quick iterations are possible, allowing for more experimental approaches.

●Enhanced accuracy and detail: High precision in reproducing intricate details.

How is 3D Printing Used in Producing Car Parts?

3D printing streamlines the production of car parts, from small knobs to large panels, using a wide array of materials.

What Types of Car Parts Are Commonly 3D Printed?

●Engine components: Custom pistons and gears.

●Interior parts: Dashboard elements, knobs.

●Exterior body panels: Custom panels for limited edition models.

●Functional prototypes: Complete subsystems tested before full-scale manufacturing.

●Custom parts and accessories: Personalized modifications for niche markets.

What Materials Are Used for 3D Printing Car Parts?

●Plastics (ABS, PLA): Lightweight and easy to mold.

●Metals (Titanium, Aluminum, Stainless Steel): Durable and heat resistant.

●Composites: For parts that require a blend of properties.

●Ceramics: Used in high-temperature environments.

How Does 3D Printing Improve Supply Chain Efficiency in Car Manufacturing?

3D printing reduces the need for extensive inventories and streamlines supply chains by allowing parts to be printed on demand, closer to the point of use. This not only cuts down on shipping costs and times but also reduces the carbon footprint associated with logistics.

What Are the Cost Implications of 3D Printing in Car Manufacturing?

How Does 3D Printing Reduce Production Costs?

●Lower material waste: Precise material usage minimizes waste.

●Reduced tooling costs: Fewer specialized tools are needed.

●Decreased labor costs: Automated printing processes require less manual labor.

●Faster time-to-market: Accelerated production cycles speed up the launch of new models.

Are There Any Cost Challenges Associated with 3D Printing in Car Manufacturing?

Initial setup costs for 3D printers and ongoing expenses for materials and maintenance can be significant. Moreover, the scale of production might not yet fully compete with traditional methods, impacting cost-effectiveness.

How Does 3D Printing Enable Customization and Personalization in the Automotive Industry?

3D printing offers consumers unprecedented options to personalize their vehicles, from custom-fit parts to unique color choices and finishes. Manufacturers can cater to individual preferences without the cost penalties typically associated with small production runs.

What Are the Environmental Impacts of 3D Printing in Car Manufacturing?

How Does 3D Printing Reduce Waste in Car Manufacturing?

●Precise material usage: Minimizes excess with exact material application.

●Recycling of materials: Some 3D printing processes allow unused materials to be recycled directly.

●Reduced need for inventory: Less storage means reduced resource use.

What Are the Energy Consumption Implications of 3D Printing?

While 3D printing is often touted for its energy efficiency, the actual consumption can vary widely based on the technology and material used. However, when compared to traditional manufacturing, the potential for energy savings is substantial, particularly when production is localized.

What Are the Limitations and Challenges of 3D Printing in Car Manufacturing?

What Are the Technical Limitations of 3D Printing in Car Manufacturing?

●Size constraints: Larger parts often require specialized industrial printers.

●Material limitations: Not all materials are suitable for high-performance parts.

●Surface finish and quality: Some printing techniques may require additional processing.

●Speed of production: While fast for prototypes, mass production speed may not yet be optimal.

How Do Intellectual Property and Regulatory Challenges Affect 3D Printing in the Automotive Industry?

Navigating the complexities of intellectual property in the age of easily replicable 3D printed parts poses significant challenges. Additionally, ensuring compliance with automotive standards and certifications for printed parts remains a critical hurdle.

How Are Major Car Manufacturers Implementing 3D Printing?

Leading automotive brands are embracing 3D printing to enhance their production capabilities and innovate further.

How is Ford Utilizing 3D Printing?

Ford has integrated 3D printing into both prototyping and parts production, reducing development time and costs.

What Are BMW’s 3D Printing Innovations?

BMW employs 3D printing for everything from prototype development to the manufacture of end-use parts in both metal and plastic.

How is General Motors Adopting 3D Printing?

GM uses 3D printing to streamline prototype development and is exploring its use in future production models.

What Role Does Tesla Play in 3D Printing in the Automotive Industry?

Tesla, known for its innovation, uses 3D printing to produce parts on-demand, reducing inventory and supporting its rapid iteration culture.

What Emerging 3D Printing Technologies Could Impact Car Manufacturing?

Emerging technologies like multi-material printing and advancements in speed and material properties could further revolutionize the automotive sector.

How Could 3D Printing Change the Automotive Industry in the Next Decade?

Predictions suggest that 3D printing will become more pervasive, driving down costs, enhancing customization, and potentially leading to entirely new designs and innovations in car manufacturing.

As we look toward the future, 3D printing stands poised to continue its disruptive trajectory in the automotive industry. With its profound implications for design, production, and supply chain management, 3D printing not only offers a glimpse into the future of car manufacturing but also heralds a new era of industrial innovation.